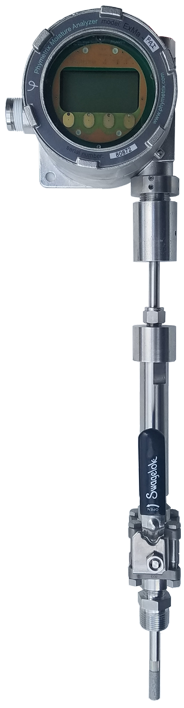

Phymetrix Explosion-Proof Moisture Probe Model: ExMa-Probe

In-situ measurement without exhausting any of the sample gas

Can be inserted into pressurized pipeline through 1/2″ or larger ball valve

Customized insertion lengths field adjustable

Unique State of the Art Features;

Menu-driven, intuitive, easy-to-use

Natural Gas Dew Point Meter

- -110°C to +20°C dewpoint Sensor

- Fast, Accurate and Repeatable Moisture Meter

- Built-in temperature compensation

- optional built-in pressure sensor with compensation

- optional 4/20 mA sink or source output

- optional RS-485 Modbus interface

- 3″ viewport, NEMA 4X/IP67 & Explosion-proof

- State-of-the-art electronics & software

- Advanced User-friendly Interface

- Continuous Status and Diagnostics display

- On-screen histogram and trend graph

- Programmable data logging, clock calendar

- Virtual Analyzer PC s/w for training & evaluation

- 316 Stainless Steel & PTFE wetted parts

- NIST calibrations

- Cost Effective Complete In-Situ System

- Thru-the-Glass Touch User Buttons

- Approved Explosion-Proof Installations USA, Canada, ATEX

- Installation Indoor/Outdoor On-The-Pipe or Panel

| natural gas dew point meter Sensor |

|

| Temperature Sensor |

|

| Pressure Sensor |

|

| Electrical |

|

| Mechanical |

|

| Temperature Range |

|

| Miscellaneous Features |

|

Standard Accessories for ExMa moisture meter:

- Pluggable Electrical Screw Terminal Connectors

- Ex Certified Side Port (3/4″ NPT) Plug

OPTIONS

| ORDERING INFORMATION | PART NUMBER |

|---|---|

| PhyMetrix Explosion Proof Moisture Probe | ExMaProbe |

| Stainless Steel Enclosure | suffix -S |

| Pressure sensor option 0-1000 psia automatic pressure correction | suffix -P |

| Mounting Legs | suffix -M |

| Analog Output 4/20 mA with HART® option | suffix -A |

| RS-485 with Modbus® option | suffix -D |

| Explosion Proof ATEX option | suffix -I |

| If Required Specify Inlet and/or Outlet Adapters |